About ASANO

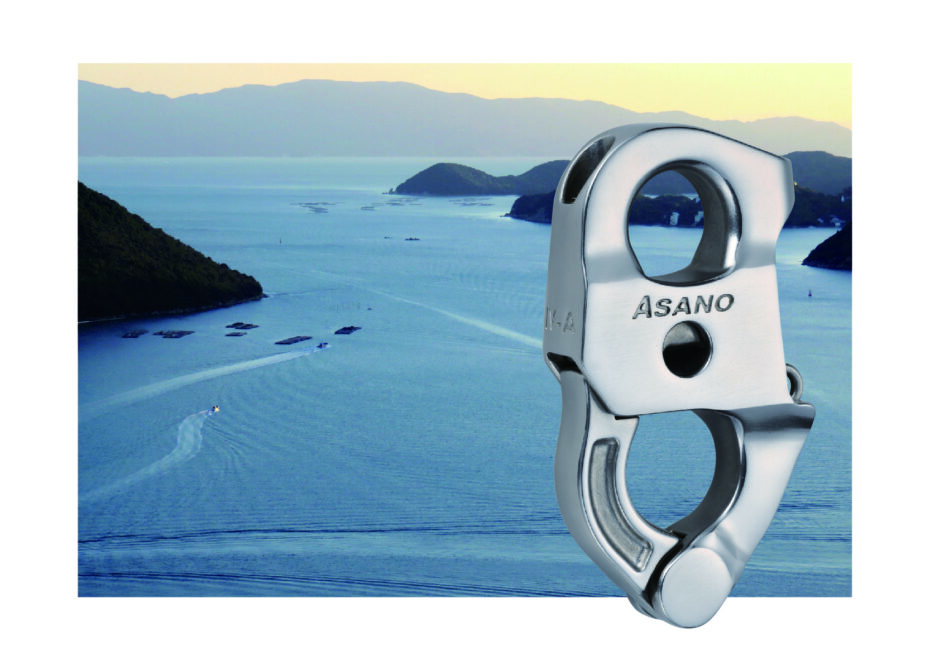

Creating stainless steel

products

which are ideal

for professional use

at sea

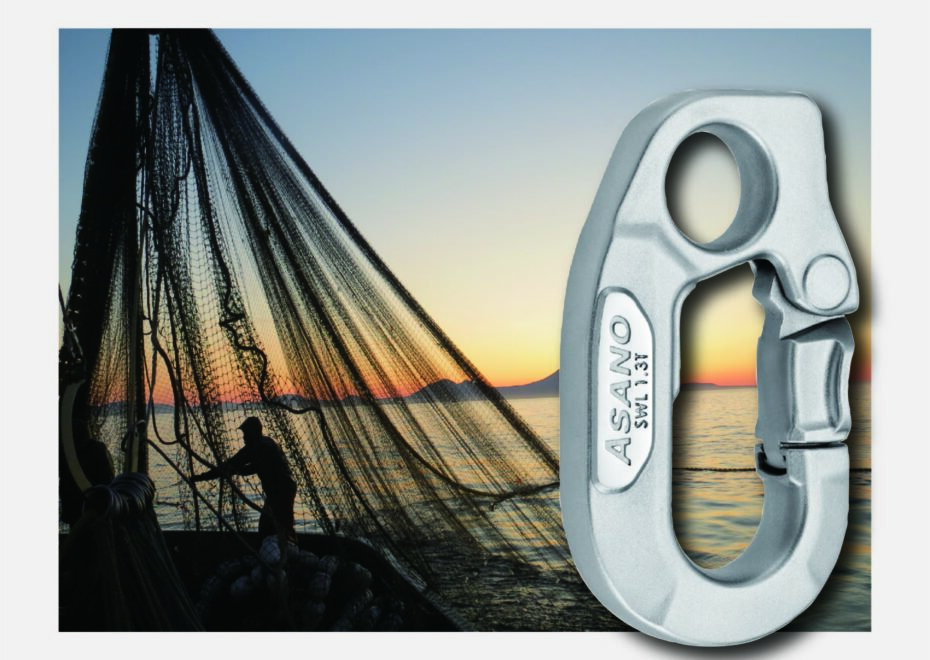

ASANO METAL INDUSTRY CO., LTD., a stainless steel product manufacturer located in Japan, that excels at planning and developing highly specialized products such as fishing hardware and blocks, has a history spanning over 70 years.

Learn more about ASANO

Products

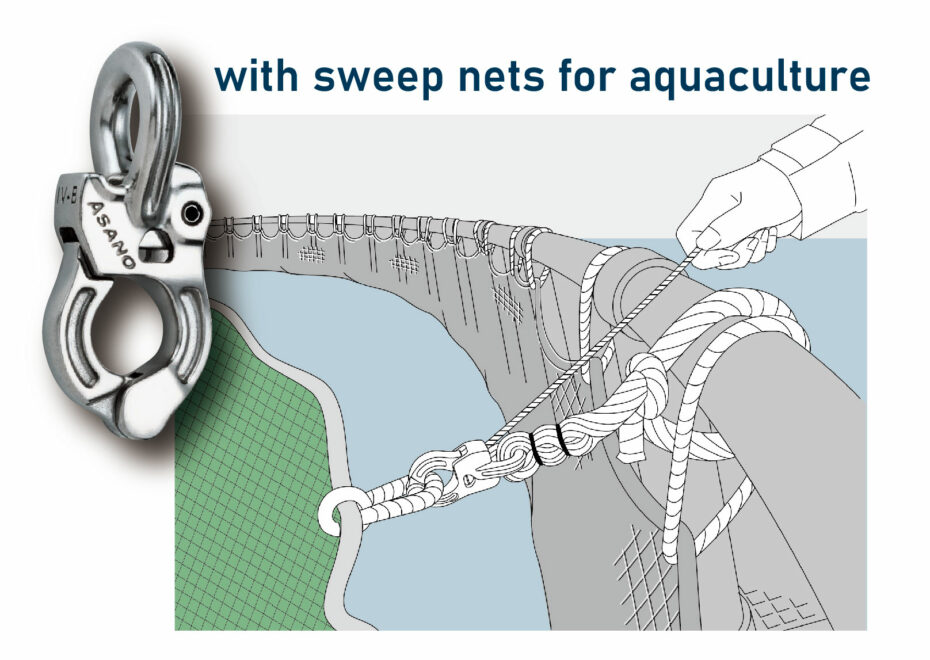

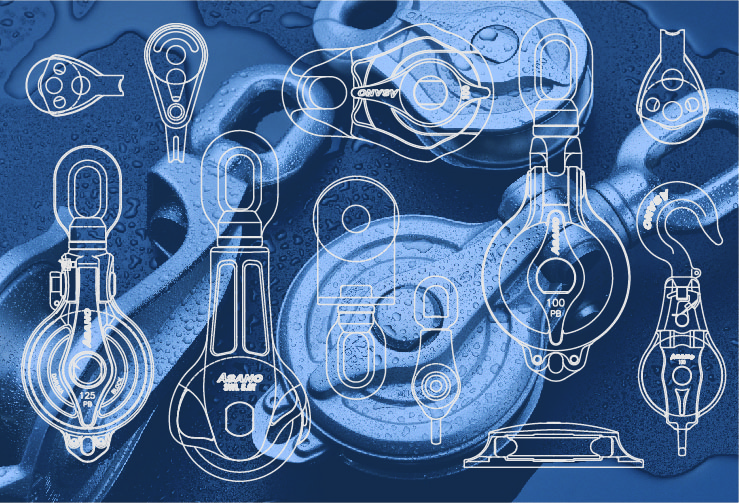

Developed with an Eye for Careful Detail, Based on User Feedback

All-Stainless-Steel Products

Drag

News

-

2024.01.26

New Product

NEW: Tender Auto Shackle

-

2023.08.29

New Product

NEW: Purse Ring Type O-ⅡA

-

2023.07.24

Others

Notice of Office Closure

Catalog

Download our catalog, featuring over 150 pages of products designed to meet the needs of a wide range of professionals.

Inquiries

For questions about our products, new business requests, dealers, and more, please contact us here.